Industrial Noise? We've Got You Covered

Everything You Need to Meet the OSHA Occupational Noise Regulations - 1910.95 & More

Occupational noise is one of the most overlooked risks in the workplace. Ignoring this hazard can result in fines or prosecution from the Regulator, as well as leave your business vulnerable to compensation claims.

Why? Exposure to excessive noise levels can cause noise-induced hearing loss or tinnitus. Hearing damage is irreversible, so it is vital to ensure you are protecting your employees and your business.

How to Protect Your Business

You must carry out regular Noise Risk Assessments and take action to reduce excessive noise exposure.

Cirrus Research is here to help you every step of the way, from choosing the right sound level meter or noise dosimeter to providing ongoing UK training and support. All of our noise measurement equipment complies with the Noise At Work Regulations, ensuring you are taking accurate measurements.

Tell us what you need today and our Noise Experts will be ready to help.

TELL US WHAT YOU NEED

Getting Started: Choose Our Recommended Instruments for Industrial Hygiene Measurements

Meeting the Regulations in Your Country

The ideal instrument for you also depends upon what regulations or standards you need to comply with. Here are some suggestions for the main Occupational Noise Regulations.

Guidance on the regulations is published in the Controlling Noise at Work booklet and states that:

".. the sound level meter should be an integrating sound level meter..." and "Your sound level meter should meet at least Class 2 of BS EN ISO 61672-1:2003 (the current instrumentation standard for sound level meters) or at least Type 2 of BS EN 60804:2001 (the former standard)".

You can also use a Class 1 or Type 1 sound level meter that meets these standards but you should never use a meter that does not meet these standards to at least Type 2 as it will not meet the requirements laid down by the HSE.

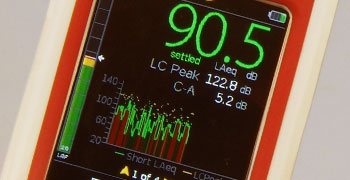

Your sound level meter should be capable of measuring:

- A weighted Leq (LAeq or LAeq,t)

- C weighted maximum C-weighted peak sound pressure (LCPeak)

You should also have a suitable acoustic calibrator to check the sound level meter before and after making any measurements.

Noise at Work Directive 2003/10/EC

Noise at Work Directive 2003/10/EC is officially known as the "Directive 2003/10/EC of the European Parliament and of the Council of 6 February 2003 on the minimum health and safety requirements regarding the exposure of workers to the risks arising from physical agents (noise)".

In the directive, the following limit and action values are defined:

- (a) exposure limit values: LEX,8h = 87 dB(A) and LCpeak = 200 Pa respectively;

- (b) upper exposure action values: LEX,8h = 85 dB(A) and LCpeak = 140 Pa respectively;

- (c) lower exposure action values: LEX,8h = 80 dB(A) and LCpeak = 112 Pa respectively.

Where:

The daily noise exposure level (LEX,8h) is the average noise exposure level for a nominal 8-hour working day as defined by ISO 1999

The peak sound pressure (LCpeak) is the maximum value of the 'C'-frequency weighted instantaneous noise pressure.

The Member States are to comply with this Directive before 15 February 2006. However, there may have an additional period of five years from 15 February 2006 with regard to limit values for personnel on board seagoing vessels. And, for the music and entertainment sectors.

Member States have a maximum transitional period of two years from 15 February 2006 (i.e. five years in total) to comply with this Directive, provided that, in the meantime, the levels of protection already achieved are maintained.

The Occupational Safety & Health Administration (OSHA) regulates sound in the workplace under standard 1910.95

These OSHA Regulations recommend the use of a Type 2 sound level meter (a Class 1 or Type 1 Sound Level Meter can also be used) with "Slow" time weighting. Your Sound Level Meter should also be calibrated using an Calibrator to check that the meter is operating correctly before making any measurements.

As of August 1981, OSHA noise exposure standards consist of a two-stage program where hearing conservation measures become mandatory at 85 dBA for an 8-hour day but feasible engineering or administrative noise controls are required when exposures exceed 90 dBA.

Hearing Conservation Programs - include annual audiometric testing and provision of hearing protectors.

Engineering Controls - include reducing machinery noise through redesign, replacement with quieter equipment or by reducing the transmission of noise along the path from source to receiver.

Administrative Controls - include reducing noise exposure by limiting the time an employee is exposed to given noise levels.

More Information

Find out more

If you have any questions or if you would like any more information, please contact us and we will be pleased to help.

From the UK, contact us on 01723 891655.

From outside the UK, please contact us on +44 1723 891655.

You can also contact us via our contact form.